Installation and maintenance of LPG systems in Tallinncost-effective solutions from GBO Eesti

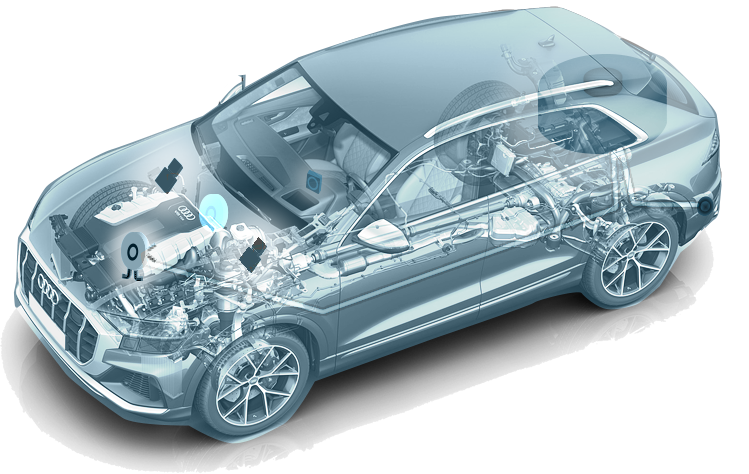

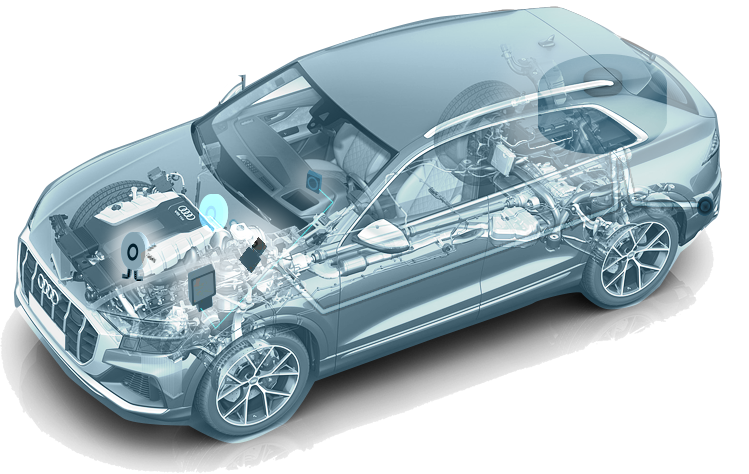

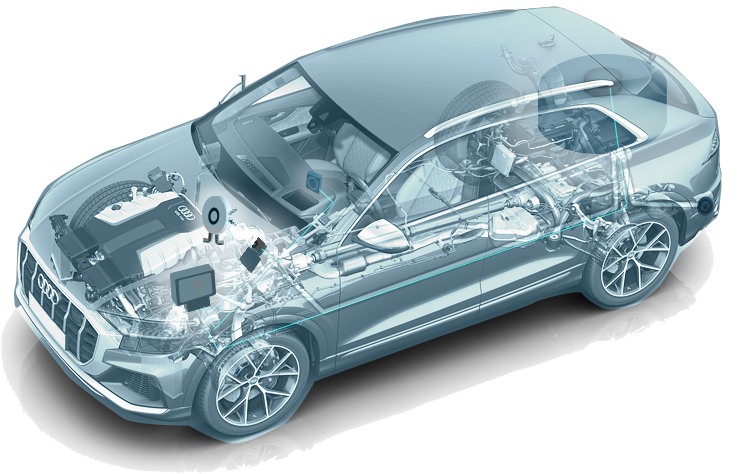

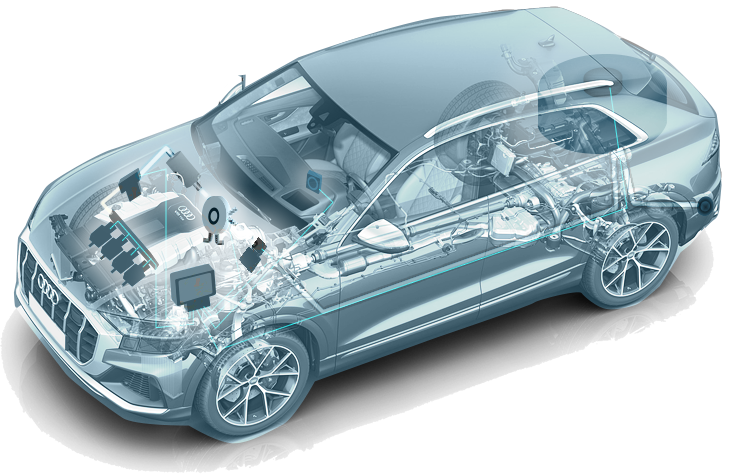

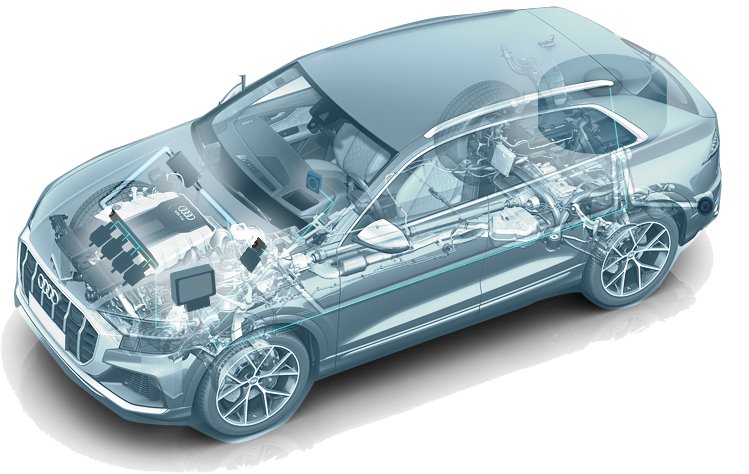

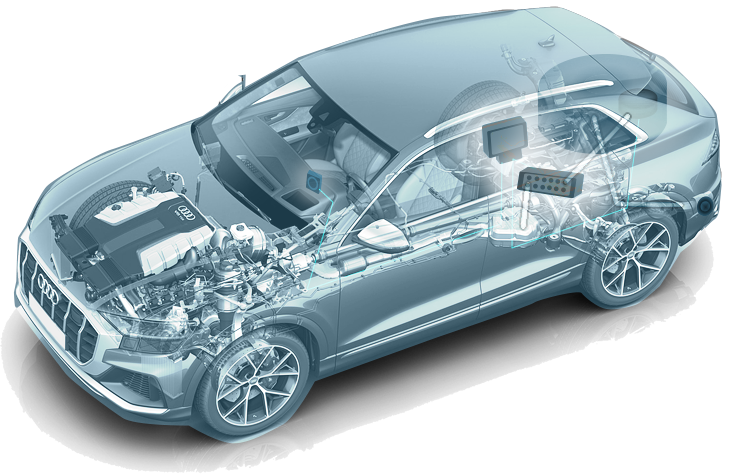

At GBO Eesti OÜ, your reliable partner for the installation of liquefied petroleum gas (LPG) systems in Tallinn, Estonia, we offer affordable LPG installation services while ensuring a high level of quality in both services and equipment used. Discover how you can significantly reduce fuel expenses and minimize your environmental footprint by choosing our cost-effective solutions.

Why GBO Eesti OÜ?

- Cost Savings and Environmental

- Friendliness With our LPG installation solutions, you not only save on fuel but also contribute to protecting the environment.

- Affordable Prices

- We guarantee high-quality services and equipment at an affordable LPG installation price.

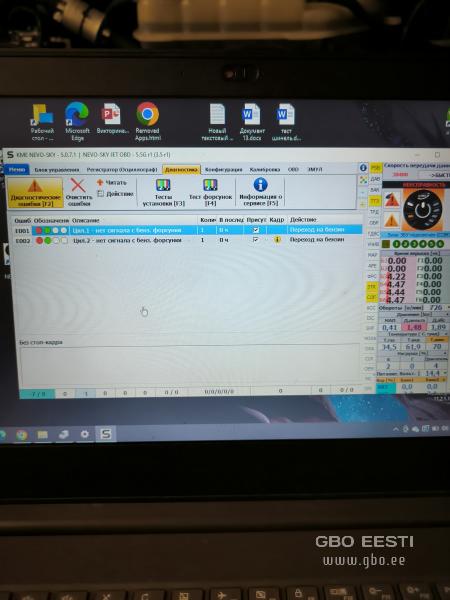

- LPG Maintenance

- Our team of experts is ready to offer a full range of services for regular maintenance of LPG systems, ensuring their long-lasting and safe operation.

- Quality Assurance

- We provide a warranty on all types of work and equipment installed.

Installing gas equipment has become one of the few opportunities to reduce fuel costs, as prices are rising almost every day. This is particularly noticeable in the transport sector, such as taxis, delivery, transport, freight transport, etc.

On average, a working vehicle travels from 1000 km per week, which is approximately 4000 km per month or 48,000 km per year. For example, for a vehicle with a fuel consumption of 10 liters per 100 km and an average mileage of 20,000 km per year, you save about 1500 euros.

By installing LPG equipment on a vehicle, you can significantly reduce expenses, with the current savings averaging 65%. On our website, you can calculate the approximate savings for your vehicle using a special calculator.

Starting from the 4th generation, gas installations are considered safer than petrol systems because they have at least two levels of protection against failure, such as when a gas line breaks, the gas equipment will automatically shut off the gas supply from the tank, unlike when petrol lines are damaged where this is not possible.

For those who doubt the advisability of installing LPG systems due to rising gas prices, we hasten to reassure that the price of LPG gas is "tied" to the price of petrol, while the price of CNG gas is "tied" to the price of gas. You can see the data on fuel price changes on our website.